| HEAT INTERCHANGERS |

Introduction | Conventional application | Increasing the suction gas temperature (superheat) | Increasing the degree of liquid subcooling as it enters the expansion valve | Evaporator booster | Air cooled condenser booster | Installation | Acknowledgements & further reading

Fig 1. Cast aluminium heat interchanger.

The use of heat interchangers, either as an aid to performance or a solution to a problem, has been custom and practice in the commercial refrigeration industry for many years, often with virtually no consideration of both theoretical or practical concepts.

They can be found applied in refrigerant systems in many different ways for many different reasons. Here we cover the most common uses these refrigerant heat interchangers.

| Conventional application. |

The most common application and original concept is to install the heat interchanger adjacent to the evaporator and thermostatic expansion valve as shown in Fig 2, below:

Fig 2. The conventional heat interchanger application.

Virtually all refrigeration systems will benefit from a heat interchanger providing it is not undersized so that the suction side pressure drop nullifies the advantages or, on low temperature applications, is oversized so that the suction superheat and consequently the discharge temperature, is too high.

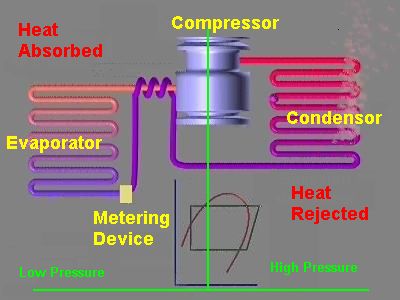

In this application the heat interchanger has two effect: increasing the gas temperature (superheat) as it enters the compressor suction and increasing the degree of liquid subcooling as it enters the expansion valve.

| Increasing the suction gas temperature (superheat) |

Most refrigeration compressors are rated at suction gas temperatures considerably above freezing point and to achieve this rating this heat must he extracted from the evaporator.

In most instances this is difficult to obtain from the evaporator in low temperature applications it is impossible, so consequently there can easily be a shortfall of 5% in the compressor rating and therefore the system capacity.

The only way that this superheat can be achieved, albeit indirectly, is from a heat interchanger which can be sized to restore and, sometimes, slightly increase the system evaporator capacity. This is achieved by superheating the suction gas and subcooling the refrigerant liquid in an exchange of heat, this sub heating then being usefully employed in the evaporator and fulfilling the requirements stated in the first paragraph.

The temperature interchange between the refrigerant vapour and the liquid is approximately equal too:

? t subcooled liquid = 'C' x ? t superheated vapour.

|

|

|

|

|

|

|

|

|

|

|

|

Liquid refrigerant entering the compressor can do considerable mechanical damage which a heat interchanger, selected for its normal duty, can prevent by boiling off or breaking up slugs of liquid refrigerant providing this is only an intermittent occurrence.

This is especially a problem on any close approach application, such as a low temperature cold store, which must operate at low TEV superheats, conditions at which instability is always likely to occur.

If "wet" refrigerant vapour continually enters the compressor it will have a detrimental effect on the lubricating system by diluting the oil and causing foaming. This can lead to excessive wear and even seizure of the moving parts.

This condition also has a de-rating effect on the pumping rate on the compressor, i.e. the system evaporator capacity, and continually washes the oil of the cylinder walls to increase the wear rate.

A heat interchanger sized for a normal duty will "dry" the refrigerant vapour and benefit the system with the related subcooling.

This arrangement utilises the cooling effect of the suction gas, which without a heat interchanger would probably be lost to the ambient in the suction line. In the heat interchanger this cooling effect is used to subcool the liquir refrigerant entering the expansion valve.

| Increasing the degree of liquid subcooling as it enters the expansion valve. |

The effective performance of the TEV and refrigeration system can only he achieved if vapour-free liquid refrigerant is available at the inlet to the TEV.

Flash gas in the liquid line, resulting from either the evaporator being mounted above the condenser and/or pressure losses in the pipelines, can be eliminated by the use of a heat interchanger.

Fig 3. Heat interchanger application to compensate for elevation pressure loss in liquid line.

Based on refrigeration liquid at 32 ºC (90 ºF) the amount of subcooling required to compensate for these losses is:

| SI & METRIC UNITS |

|

|

|

| 1 bar pressure drop |

|

|

|

| 10m elevation difference* |

|

|

|

| IMPERIAL UNITS |

|

|

|

| 10 psi pressure drop |

|

|

3.6 ºF |

| 10ft elevation difference* |

|

|

|

Minimum heat interchanger superheats and the approximate related subcooling for nominal selection are: -

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The total system superheat is the above plus the TEV superheat and the subcooling is the above plus the condenser subcooling which for a condenser without a special subcooling section is about YK (5 ºF)

A realistic appraisal of heat interchanger usage would be:

| APPLICATION | USAGE |

| High temperature | Recommended |

| Commercial temperature | Essential |

| Low temperature | Essential |

| Evaporator booster. |

Any direct expansion evaporator will perform at its best when the suction gas superheat is low and it is possible to achieve this if the major part of the TEV superheat is obtained from the heat interchanger.

When a heat interchanger is used in this manner the majority of the advantages listed are not applicable and it is possible on systems where the TEV is set far too low that the system will become very unstable due to the erratic temperature of the sub-cooled liquid.

This can he overcome by increasing the superheat to a more reasonable level which will achieve the objective of increasing the evaporator performance without any undue instability.

A heat interchanger selected for this type of application can be chosen for its superheating ability or the suction side pressure drop when this data is available.

| Air cooled condenser booster. |

Only the cast aluminium type of heat interchanger can be used on this application. Air cooled condensers suffer from the fact that when their maximum performance is required the ambient air temperature is high. However, as this may only occur on a few days a year, it could be uneconomical to size the condenser for this temperature.

The use of a heat interchanger in the refrigerant discharge line between the compressor and condenser with water connected UP to the smaller connections will be capable of boosting the condenser capacity to that of a water cooled type while still retaining the advantages of the former.

For maximum utilisation of the water a refrigeration condenser pressure operated water valve should be fitted to allow water to flow through the heat interchanger when the pressure rises above a pre-set value

| Installation |

Most heat interchangers can be fitted in any location except that the larger steel type with the offset suction connection should be fitted with this connection below the centreline when fitting horizontally to prevent excessive oil trapping.

To eliminate any possibility of hydraulic damage from ice build up during pump down the liquid line solenoid valve should be fitted between the heat interchanger and the TEV as shown on the appropriate sketches.

| Acknowledgements & Further reading. |

Refrigeration, Air Conditioning and Heat Recovery, October, 1982

John Gillan, of the research and development department, Searle Manufacturing Company.

H.R.P. Catalogue 1996.